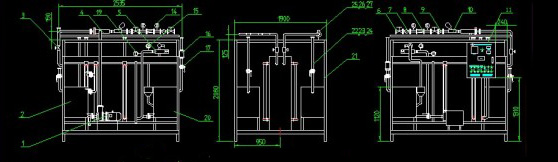

Plate UHT Sterilizer Introduction

Sterilization is an indispensable step of juice beverage before filling and packing. Plate UHT sterilizer is ideal equipment for sterilization of milk, beverage and other fluid materials. Its sterilization temperature is 137。C, warm keeping time is for 3 to 5 seconds, so to keep the original color, nutrition, and flavor of the beverage and dairy.

Plate UHT Sterilizer Features

- The Capacity: is from 1 to 10T/h.

- Plate heat exchanger for sterilization.

- The medium for heating is high pressure steam.

- High heat recycle, compact and fine structure, and temperature control.

- Control outputting material temperature, and cool package.

- Plate and fluid piping are made of high-quality stainless steel 304.

- Inadequate temperature or malfunction of filling and packing system can make the fluid materials automatic reflux.

Plate UHT Sterilizer Application

The Plate UHT sterilizer integrates the process of preheating, sterilization, heat preservation and cooling together, widely used for sterilization of food, milk, beverage, fruit juice, vinegar, wine and other similar fluids.Working Principle of the Plate UHT Sterilizer

The working principle of the plate UHT sterilizer is to use steam to heat room temperature water to superheat hot water through the plate heat exchanger, and then use superheated water to heat the material between walls, heat it to the specified temperature and keep it warm, the holding time is usually a few seconds, and then cool down or directly enter the next process according to the requirements. The cooling method is generally carried out in two steps: the first step is to use the material to preheat the feed, and the second step is to use ice water to further cool the material, and then enter the next process. The above process should be determined according to the specific production process requirements.

Whether the sterilization temperature can meet the design requirements is related to the calculation of the heat exchange area at each stage of the sterilization process. The calculation of the heat exchange area of this plate sterilizer includes two parts, one is the material preheating section and the other is the material sterilization section. Whether the plate UHT sterilizer can achieve the effect, the most critical influencing factor is whether the heat exchange area, that is, the preheating area and sterilization area, is sufficient and whether the control is reasonable and accurate. Secondly, production must be carried out in strict accordance with automatic operating procedures, otherwise, it is difficult to meet production needs.

Installation and Maintenance of the Plate UHT Sterilizer

- Each instrument control valve should have a special person responsible for operation and maintenance following the relevant instructions.

- Regularly check whether each heat exchanger sheet is clean, whether there is sediment, coking and rust layer adhering, etc., and remove it in time. At the same time, check whether the bonding between each heat exchange sheet and the rubber pad is intact to avoid leakage caused by degumming and damage to the rubber pad.

- When pressing, it should be in accordance with the specified size requirements, and should not be pressed too tightly to ensure that it does not leak. If the leakage does not stop after heating, a comprehensive inspection should be carried out. Generally, leakage occurs at the beginning of the test run, and the leakage stops as the heating temperature rises.

- The instrument box should be properly grounded, and the total power supply should be cut off during the inspection. The instrument box should be placed in a relatively dry position and properly put in the desiccant.

- During the operation of the equipment, the operator should always pay attention to whether the steam pressure is stable, whether the water heater is short of water, whether the balance tank is broken, whether the steam regulating valve, return valve, and instrument are normal, and if there is a fault, it should be eliminated in time.

Packing and Delivery