Quick freezing technology is key to locking in the natural taste, nutrition, and freshness of food. Slow freezing processes damage food cells, leading to drip loss and a mushy texture, whereas quick freezing forms tiny ice crystals, perfectly preserving the food's original state.

What is a IQF Spiral Freezer?

Single drum spiral freezer

Single drum spiral freezer

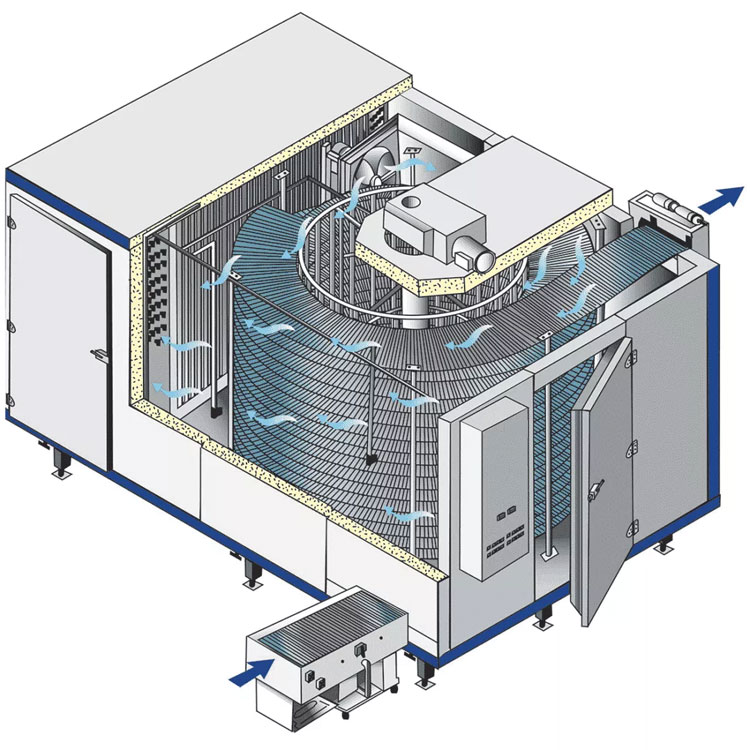

A Spiral Freezer is an advanced continuous freezing equipment. Its core design features a conveyor belt that spirals up or down within a vertical space, allowing products to be exposed to high-intensity, low-temperature airflow in a controlled environment, achieving rapid and uniform freezing. This design perfectly solves the industrial challenge of achieving large-scale, high-efficiency freezing within a limited footprint.

Double spiral quick freezing machine

Double spiral quick freezing machine

AGICO Spiral Quick Freezing Machine Features:

- High Space Efficiency: Compact vertical design, small footprint, large processing capacity.

- Strong Product Versatility: Capable of handling various products, from uniform meat cuts to delicate berries, from fragile pastries to sticky fillings.

- Exceptional Freezing Quality: Achieves genuine Individual Quick Freezing, perfectly maintaining product form and intrinsic quality.

- High Automation Level: Continuous automatic operation, significantly saves labor, seamlessly integrates with upstream and downstream production lines.

Working Principle & Process

The AGICO Spiral Freezer ensures each product achieves optimal freezing results through a precise, continuous process.

1. Uniform Loading

The products to be frozen are conveyed steadily and evenly to the entrance of the spiral tower via an infeed conveyor belt, ensuring even distribution on the mesh belt, laying the foundation for efficient freezing.

2. Spiral Path Freezing

Products enter the interior of the spiral tower and are guided by the sturdy mesh conveyor belt on a spiral descent or ascent. This design significantly extends the product's path and residence time within the effective freezing zone, ensuring thorough freezing.

3. Forced Convection Heat Exchange

This is the core stage for achieving rapid freezing. High-efficiency fan systems located at the top of the unit generate a powerful, top-down flow of low-temperature air (-35°C to -40°C). This airflow penetrates the product layer vertically, removing heat with maximum efficiency.

Technical Key: Our optimized airflow organization ensures full contact between the "cold air" and the "product," maximizing heat exchange efficiency. This rapid heat transfer causes the moisture inside the product to quickly pass through the zone of maximum ice crystal formation, creating fine ice crystals that protect the cellular structure.

4. Stable Discharge

Products that have completed the predetermined freezing time are discharged steadily from the other end of the spiral tower. The discharge temperature meets or exceeds the standard -18°C, and products are individually separated, ready for direct packaging or storage.

Packged Spiral Freezer

Packged Spiral Freezer

Advantages: Why Choose the AGICO IQF Spiral Freezing Machine?

Superior Space Efficiency

Our vertical spiral design is a model of space optimization. Within the same footprint, it provides a conveyor belt several times longer than traditional tunnel freezers, enabling greater processing capacity, especially suitable for modern factories with space constraints.

Outstanding Product Quality

Leveraging efficient IQF technology, the AGICO Spiral Freezer ensures product cell structure remains intact, with minimal drip loss after thawing. This means your products can consistently maintain vibrant color, firm texture, and pure flavor, building market reputation.

High Production Flexibility & Versatility

Whether it's uniformly shaped patties and nuggets, fragile strawberries and blueberries, or sticky prepared meals and fillings, our equipment handles them with ease. Flexible belt speed adjustment allows the same unit to adapt the freezing time to various product requirements.

Optimized Energy Consumption & Efficiency

Through high-efficiency insulated panels, precise PLC temperature control systems, and optimized airflow design, we minimize cold loss. The continuous operation mode avoids energy waste associated with frequent door opening in batch freezing, significantly reducing your long-term operating costs.

Robust and Durable Hygienic Design

The main structure and product contact parts are extensively constructed using SUS304 stainless steel, fully compliant with food safety and hygiene standards (e.g., HACCP, CE). Smooth surfaces with no sanitary dead corners make cleaning and maintenance easy. The sturdy construction ensures the equipment can handle continuous, high-intensity operation 24/7.

Product Specifications & Customization Options

AGICO offers a range of standard models and emphasizes providing customers with deep customization services.

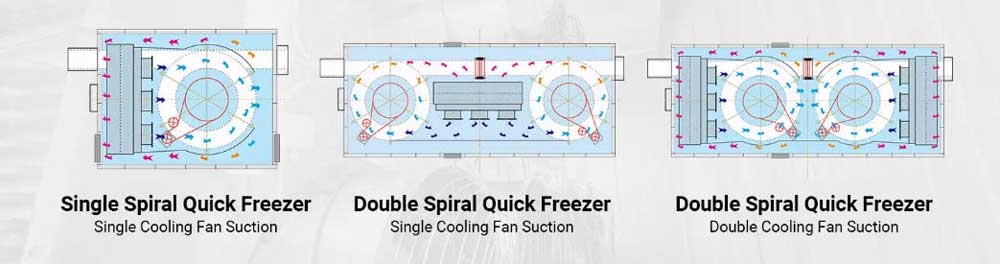

Types of IQF Spiral Freezing Machine

Types of IQF Spiral Freezing Machine

Parameter Description

| Model | LSD1-500 | LSD1-1000 | LSD2-1000 | LSD2-2000 | LSD2-3000 |

|---|---|---|---|---|---|

| Throughput(kg/h) | 500 | 1000 | 1000 | 2000 | 3000 |

| External Dimension L×W×H(mm) | 6500x4440x3520 | 7000x5400x4200 | 12600x4440x3520 | 13800x5400x4200 | 16260x6000x4510 |

| Feed Temperature(℃) | +15 | ||||

| Discharge Temperature(℃) | -18 | ||||

| Freezing Time(min) | 20–60 | ||||

| Cryogen | R507/R404 | ||||

Our Customization Service:

We understand that every factory and product is unique. The AGICO team can tailor the most cost-effective spiral freezing solution for you based on your specific product characteristics, desired capacity, plant layout, and budget.

Get Your Custom Freezing SolutionApplication Scenarios & Industries

The AGICO Spiral Freezer is the ideal choice for the following fields:

Primary Industries:

Food processing plants, central kitchens, prepared meal manufacturers, meat and aquatic product processing plants, frozen fruit and vegetable processing plants.Typical Application Products:

- Meat & Poultry: Burger patties, chicken nuggets, steaks, meatballs.

- Aquatic Products: Fish fillets, shrimp, scallops, crab sticks.

- Prepared Foods: Dumplings, spring rolls, pizza, pasta, cakes.

- Fruit & Vegetable Products: Fruit dices, mixed vegetables, french fries, corn kernels.

Our Commitment

As a trusted partner in the food industrial equipment sector, AGICO is committed to integrating cutting-edge engineering technology with stringent quality standards. We deliver not just equipment, but a comprehensive solution—from initial consultation and system design to equipment manufacturing, installation, commissioning, and after-sales support.

Share your product details and production requirements with us, and our expert team will promptly provide you with a detailed technical proposal and a highly competitive quote.

-lp.jpg)