AGICO small food freeze dryer for home use (also known as a small food lyophilizer) utilizes high-quality imported core components, ensuring stable and reliable performance. The food freeze drying equipment features an aesthetically pleasing design, compact structure, and user-friendly operation, making it ideal for efficient freeze-drying needs in laboratories, food processing shops, and small to medium-scale production facilities.

The HFD series home food freeze dryer breaks through the limitations of traditional manual operation by integrating in-situ pre-freezing and drying, significantly enhancing process convenience. The second-generation upgraded version fully incorporates a PLC intelligent control system, enabling one-touch automated operation. It is widely used for fruits, vegetables, meats, aquatic products, traditional Chinese medicines, health products, pet food, instant beverages, and more.

What is Freeze-Drying? The Gold Standard in Food Preservation

Freeze-drying (lyophilization) is the most effective method to preserve food. It's a gentle, three-stage process that removes moisture without damaging the food's cellular structure:

- Deep Freezing: The unit rapidly freezes the food solid at ultra-low temperatures.

- Vacuum Chamber: A powerful vacuum is created, allowing the frozen ice to sublimate directly from solid to vapor.

- Primary Drying: Low, gentle heat accelerates sublimation, while a high-capacity cold trap captures all released vapor.

Unit Features of AGICO Home Food Freeze Dryer

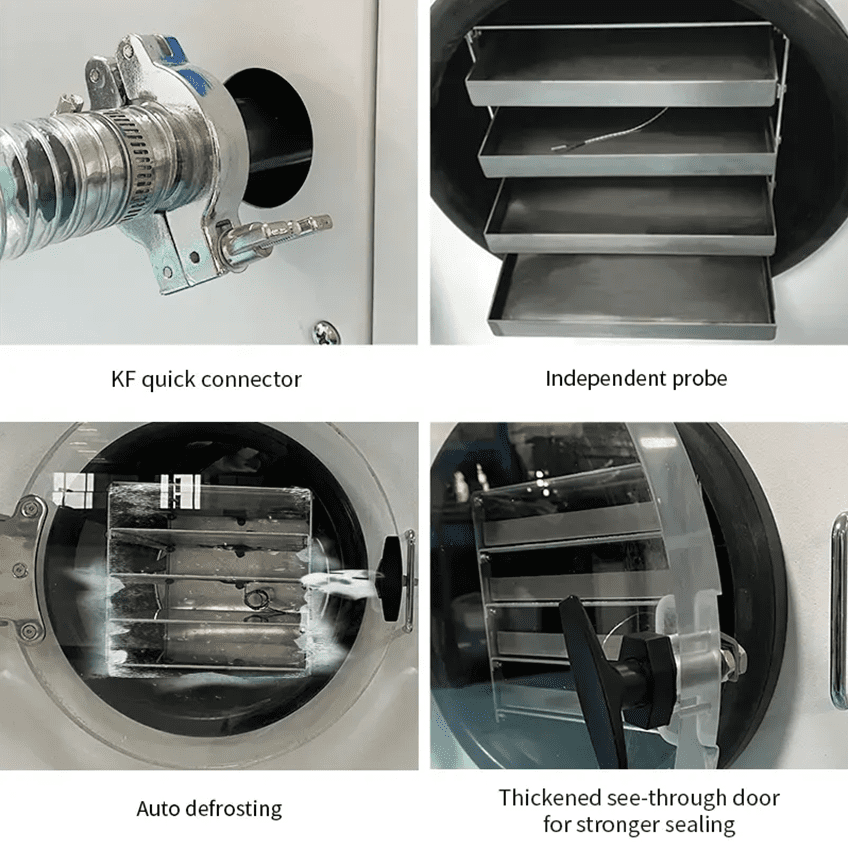

- Integrated In-Situ Pre-freezing and Drying design eliminates material transfer steps and avoids contamination;

- Programmable multi-stage temperature control allows customized freeze-drying processes for different materials, improving final product quality;

- Parameters can be modified in real-time during operation, supporting online recording of drying curves and data for process tracing and analysis;

- User-friendly human-machine touchscreen interface supports user password setting and real-time display of freeze-drying curves for intuitive and simple operation;

- Square food-grade 304 stainless steel trays are sturdy, corrosion-resistant, and easy to clean, suitable for various materials;

- Equipped with a standard gas filling valve; optional inert gas filling function facilitates protection of oxidation-prone materials;

- High-transparency colorless acrylic door allows full visual monitoring for real-time observation of material status and sublimation process;

- TF-HFD-1/TF-HFD-4 models offer an optional oil-free vacuum pump, thoroughly resolving issues of oil mist contamination and vacuum pump corrosion;

- TF-HFD-4/TF-HFD-6 models are equipped with a PLC control system, enabling one-touch start and fully automated control.

|

Model |

TF-HFD-1 |

TF-HFD-4 |

TF-HFD-6 |

|---|---|---|---|

|

Shelf Area |

0.1㎡ |

0.4㎡ |

0.6㎡ |

|

Cold Trap Temperature |

-40℃ |

||

|

Chamber Vacuum Degree |

≤10Pa |

||

|

Batch Processing Capacity (KG/Batch) |

1 |

4 |

6 |

|

Shelf Spacing (mm) |

45 |

45 |

70 |

|

Heating Method |

Electric Heating |

||

|

Power Supply |

220V;50HZ |

||

|

Power (W)) |

750W |

1100W |

2300W |

|

Tray Size (W*L) |

145*275mm |

195*425mm |

345*425mm |

|

Number of Trays |

3 |

4 |

4 |

|

Overall Dimensions (W*D*H) |

400*550*700mm |

550*800*850mm |

72*71*1135mm |

|

Net Weigh |

50kg |

162kg |

220kg |

|

Shipping Weight |

95kg |

193kg |

250kg |

|

Control System |

Real-time display of shelf freeze-drying curve and temperature curve, intelligent temperature contro |

||

|

Defrosting |

One-touch defrosting function |

||

Function of Food Freeze Drying Machine

- In-situ freeze-drying with one-touch start for intelligent operation

- Multi-stage programmable temperature control with process prompts and monitoring

- Real-time display and recording of temperature curves and vacuum data, supporting USB export

- Touchscreen + PLC control, supports access management and data storage

- Square stainless steel trays, deformation-resistant and easy to clean, suitable for diverse production needs

- Dual protection mechanism for temperature and vacuum level ensures stable equipment operation

- Transparent drying chamber design allows real-time observation of the entire freeze-drying process

- Supports both "Program Control" and "Vacuum Control" modes to adapt to different process requirements

- One-touch defrost function improves equipment cleaning and maintenance efficiency

- Intelligently records freeze-drying data, supports curve playback and process optimization

Types of Food You Can Freeze Dry (You can freeze dry almost anything)

- Fruits: Strawberries, blueberries, apple slices, banana slices, mango, etc. They become crunchy snacks with concentrated sweetness.

- Vegetables: Diced carrots, corn, peas, mushroom slices. Perfect for soups or snacks.

- Meat & Seafood: Chicken, beef, shrimp (must be cooked first). Ideal for high-quality pet treats or human protein snacks.

- Dairy & Cooked Meals: Yogurt drops, cheese, ice cream chunks, cooked rice or pasta. Creates interesting textures.

- Drinks & Soups: Coffee, fruit juice, thick soups. Spread thinly and freeze-dry to make instant dissolving blocks.

- Pet Treats: This is a major use case. Make additive-free pure meat or vegetable treats for cats and dogs.

Main Applications and Uses

- Food Preservation: Extends shelf life to years, helps manage seasonal produce gluts, and reduces food waste.

- Healthy Snacks: Make sugar-free, additive-free fruit and vegetable snacks for a healthier family option.

- Outdoor & Emergency Prep: Make lightweight, portable food for hiking/camping. Serve as long-term emergency food storage.

- Pet Care: Create safe, transparent, and healthy pure meat treats and supplements for your pets.

- Creative Cooking: Use for decorations in baking/desserts, or make homemade powders (like garlic powder, herb powder).

Our Promise to You

We don't just sell a machine; we offer a long-term partnership in your food preservation journey.

- Robust Warranty: Industry-leading 2-year full warranty and a 10-year compressor warranty guarantee your investment.

- Expert Support: Access to a dedicated team for troubleshooting and advice.

- Global Shipping & Service: Reliable logistics and local service networks.

Frequently Asked Questions (FAQ)

Q: How long does a typical cycle take?

A: Cycle time varies from 20 to 36 hours, depending on food type, thickness, and water content. The touchscreen provides real-time progress updates.

Q: How do I clean the machine?

A: Maintenance is simple. The stainless steel trays are dishwasher safe. The chamber requires only a wipe-down. The pump requires periodic oil changes (if oil model is used).

Q: What is the difference between an oil and oil-free pump?

A: Oil pumps are highly efficient and are standard. Oil-free pumps are quieter and require less maintenance but may come at a premium. We offer both to suit your needs.

-lp.jpg)