AGICO Mango Dehydrator Hot Air Circulation Drying Machine

The CT-C series hot air circulation fruit and vegetable dryer produced by AGICO is a high-efficiency, energy-saving device specifically designed for the industrial drying of mangoes and other agricultural and sideline products. By integrating international advanced technologies with localized production advantages, we are committed to providing customers with drying solutions that feature high thermal efficiency, uniform drying, and stable operation. This helps enterprises significantly reduce energy consumption costs while enhancing product quality and economic benefits.

As a leading drying equipment manufacturer in the industry, AGICO drying ovens strictly adhere to relevant national industry standards (unified model RXH). Their successful design has elevated China's hot air circulation drying technology to advanced levels domestically and internationally. Our equipment is widely used in various fields such as food processing, pharmaceuticals, and chemicals, making it an ideal choice for the large-scale production of dried mango slices and similar products.

In dried mango production, drying is the decisive stage for the final product's color, texture, nutrition, and value. AGICO’s professional mango dryer is not just a heater—it is a precision drying system that integrates thermodynamics, intelligent control, and food science, preserving the authentic flavor and quality of mangoes in the most scientific and economical way.

Why is specialized equipment essential? Mangoes are sensitive to temperature and airflow. Traditional drying often results in uneven quality, nutrient loss, low efficiency, and high energy waste. The AGICO dryer turns drying from an uncontrollable step into a consistent and adjustable core advantage.

Hot Air Circulation System Technology and Working Principle

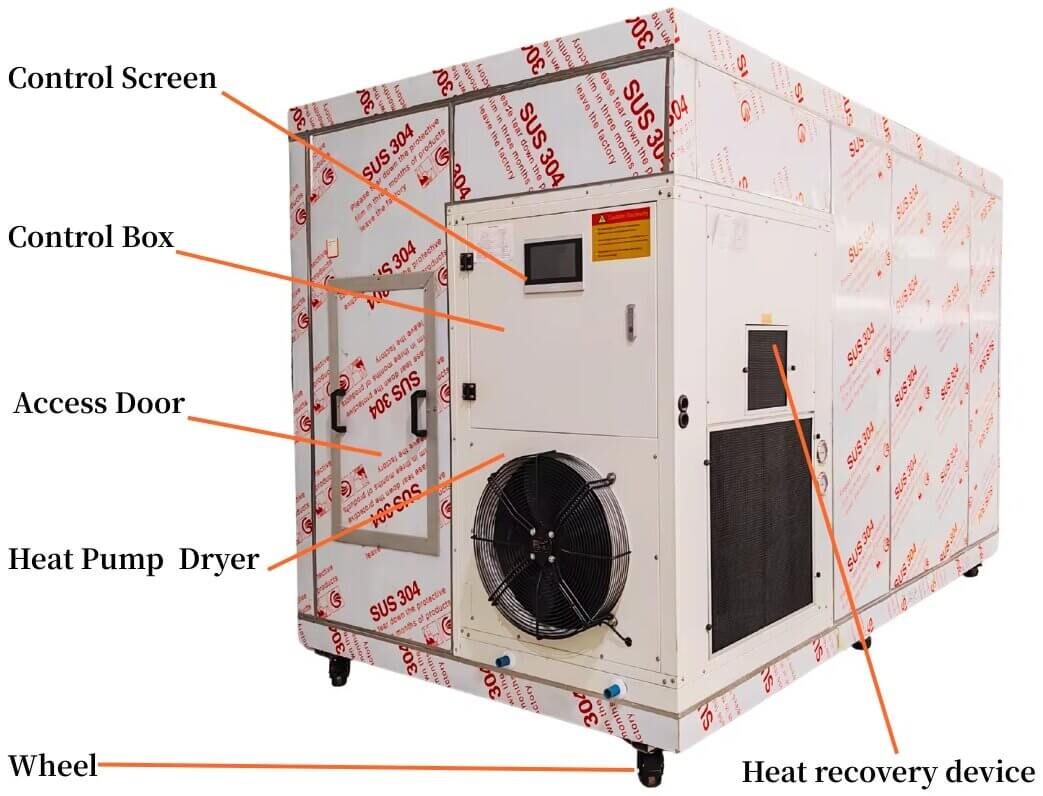

The core technology of AGICO drying ovens lies in their fully enclosed hot air circulation system. The equipment is equipped with a low-noise, high-temperature-resistant axial flow fan and an automatic temperature control system, which drives hot air to circulate in a closed loop within the drying chamber.

- Revolutionary Improvement in Thermal Efficiency: This design dramatically increases the average thermal efficiency of the equipment from 3%-7% in traditional drying rooms to 45%-50%, with maximum thermal efficiency reaching up to 60%, achieving significant energy savings.

- Guarantee of Uniform Drying: Through forced ventilation and adjustable air distribution plates inside the chamber, hot air evenly passes through each layer of material, ensuring consistent heating and uniform drying quality of mango slices.

Heating Options

To accommodate different production conditions of our customers, we offer a variety of heat source options:

- Steam Heating: Suitable temperature range 50–140°C, max 150°C.

- Electric Heating: Suitable temperature range 50–650°C, providing precise temperature control.

- Hot Water / Thermal Oil / Hot Air Furnace Heating: Meets medium to high-temperature drying needs, up to 300°C.

Advantages of AGICO Mango Dehydrator

Excellent Sealing Performance: Utilizes a fully sealed chamber structure and a unique guide rail sealing mechanism to minimize heat loss and ensure high efficiency and energy savings.

Precise temperature control: The temperature difference between the upper and lower layers inside the chamber can be controlled within ±2°C, effectively eliminating inconsistent drying caused by uneven heat distribution.

User-Friendly and Safe Design:

- Quick-Disassembly Design: All internal components can be easily disassembled and reinstalled, facilitating thorough cleaning and maintenance.

- Dual-Door Mechanical Interlock (for double-door models): Prevents both doors from being opened simultaneously, ensuring safety and heat retention.

- Low-Noise and Stable Operation: Creates a better working environment.

Intelligent Control System: Can be equipped with optional text display or touchscreen control systems for simple operation, enabling precise programming and monitoring of the drying process.

Robust and Durable Construction: Main contact parts are made of high-quality stainless steel (e.g., SUS304), complying with food hygiene requirements. Some models are designed to meet pharmaceutical "GMP" standards, offering durability and ease of cleaning.

Contact us for product catalog

Contact us for product catalog

Mango Drying Oven Model and Specification

The following are specifications for part of AGICO's standard CT-C series mango drying oven models. Customers can choose based on production capacity requirements. We also support comprehensive customization services.

| Spec. of industry standard | specification | Batch drying capacity(kg) | Power(kW) | Steam to be consumed(kg/h) | Heat exchange area(㎡) | Velocity(m3) | Temperature different of the top and the bottom(℃) | Baking trays | Overall dimensions (LxWxH)mm | Baking cart to be used (set) |

|---|---|---|---|---|---|---|---|---|---|---|

| RXH-5-C | CT-C-O | 25 | 5 | 5 | 5 | 3400 | ±2 | 8 | 1400x1200x1600 | 0 |

| RXH-14-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1400x1200x2000 | 1 |

| RXH-14-C | CT-C-Ⅰ | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300x1200x2000 | 2 |

| RXH-27-C | CT-C-Ⅱ | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300x2200x2000 | 4 |

| RXH-41-C | CT-C-Ⅲ | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300x3220x2000 | 6 |

| RXH-54-C | CT-C-Ⅳ | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4450x2200x2000 | 8 |

| RHX-25-A | High effect and high temperature far infrared sterilization oven. The power will be equipped in accordance with the requirements of temperature. | 1200x1000x1600 | ||||||||

Note: Drying capacity is based on test data of conventional materials. Actual output may vary depending on the initial moisture content of the material, slice thickness, and drying requirements. We provide professional model selection consulting services.

The Integrated Mango Drying Processing Line

1. Pre-processing Unit: Fully Automatic Mango Peeling and Destoning Machine

As the efficient starting point of the line, this unit aims to completely replace labor-intensive manual operations.

- Integrated Operation: A single machine integrates three core processes: washing, peeling, and destoning (pulping), enabling automated assembly-line operation with a maximum capacity of up to 20 tons/hour.

- High-Yield Core Technology: Employs contour-following peeling and precision centering destoning technology to minimize flesh waste, ensuring a pulp recovery rate as high as 99.5%. The peeled fruit surface is smooth, laying the foundation for subsequent uniform drying.

- Food-Grade Engineering Design: All contact parts are made of SUS304 stainless steel, complying with HACCP hygiene standards. The equipment has no sanitary dead corners and supports quick disassembly and cleaning.

- Flexible Configuration Modes: Can operate as a standalone unit or be seamlessly integrated into a complete automated production line.

Mango Peeling Machine and Destoner Technical Parameters

| Type | Capacity(t/h) | Power(kw) | Size(mm) | Weight(kg) |

|---|---|---|---|---|

| M LX-5 | 5 | 7.5 | 1900*800*1650 | 970 |

| M LX-10 | 10 | 11 | 2200*900*1750 | 1020 |

| M LX-20 | 20 | 15 | 2500*1020*1780 | 1200 |

2. Drying Unit: CT-C Series Heat Circulation Ovens

Multi‑source heating, wide adaptability: Compatible with steam, hot water, electricity, thermal oil, hot air furnaces, and other heat sources, seamlessly integrating with existing infrastructure in various plants.

Uniform drying technology: Equipped with adjustable air ducts and airflow equalizing plates, combined with low‑noise, high‑temperature resistant axial fans, to achieve forced vertical circulation of hot air inside the chamber. This ensures consistent drying results across both upper and lower tray layers.

Complete model range: From the CT‑C‑O model (25 kg/batch) suitable for R&D and small‑scale trials, to the CT‑C‑IV model (400 kg/batch) designed for large‑scale production — offering a full spectrum of options.

Applications

AGICO drying ovens are not only experts in mango drying; their versatility meets the drying needs of various materials:

- Fruits: Mango, banana, lemon, apple, kiwifruit, strawberry, blueberry, etc., for making dried fruits.

- Vegetables: Carrot, cucumber, onion, garlic, chili pepper, edible fungi, etc., for dehydrated vegetables.

- Other Categories: Chinese herbal medicines, jerky, fish, chemical raw materials, industrial component baking, etc.

AGICO Service and Support

Choosing AGICO means you will receive reliable support throughout the entire lifecycle of the equipment.

- Customized Design and Production: During the design and production stages, we will fully consider your site conditions and utility requirements to ensure optimal equipment configuration and perfect integration with your production line.

- Professional Installation and Commissioning: After the equipment arrives, we can dispatch dedicated technical personnel to guide on-site installation and be responsible for commissioning until normal operation is achieved.

- Comprehensive Operation Training: Before the equipment is put into use, our commissioning personnel will provide systematic training for your relevant staff, covering equipment maintenance, common troubleshooting, and standard operating procedures.

- Reliable Quality Assurance: All equipment comes with a one-year warranty. During the warranty period, free repair or replacement will be provided for malfunctions caused by non-human factors.

- Lifetime Technical Support: We promise to provide lifelong technical consulting services and supply high-quality spare parts at competitive prices.

Mango Peeling and Destoning Machine

Mango Peeling and Destoning Machine

-lp.jpg)