In today's world, where traditional freezing technologies often fail to meet high-quality freezing demands, AGICO leverages its profound expertise in industrial refrigeration to introduce a new generation Liquid Nitrogen Cabinet Freezer. Utilizing innovative cryogenic technology, this equipment thoroughly addresses industry pain points such as significant ice crystal damage, quality degradation, and low efficiency commonly associated with conventional freezing processes. It provides a revolutionary freezing solution for sectors including food processing and biomedical industries.

Get a free quote

Get a free quote

What is a Liquid Nitrogen Cabinet Freezer?

The AGICO Liquid Nitrogen Cabinet Freezer is a high-performance freezing unit developed based on advanced cryogenic technology. Its core principle involves using liquid nitrogen with a boiling point as low as -196°C as the refrigerant. Through a precisely designed spraying system and an intelligent temperature control system, an ultra-low temperature environment is rapidly established within the enclosed cabinet. This unique working principle enables products to quickly pass through the maximum ice crystal formation zone (0°C to -5°C) within minutes, achieving vitrification freezing of the material.

Compared to traditional mechanical freezing equipment, the AGICO Liquid Nitrogen Cabinet Freezer offers unparalleled advantages. It avoids the formation of large ice crystals that occur during slow freezing processes, which can puncture cell membranes and lead to drip loss, texture damage, and loss of flavor compounds. By achieving rapid and deep freezing, the unit maximizes the preservation of the material's cellular structure integrity, ensuring that the frozen products retain quality characteristics close to their fresh state after thawing.

Features of AGICO Liquid Nitrogen Cabinet Freezer

- Material Stand: Mobile and adjustable 304 stainless steel stand with an integrated circulation system.

- Refrigeration System: Liquid nitrogen vaporization refrigeration system, featuring dual solenoid valve temperature control and variable-frequency dual-fan circulating refrigeration.

- Insulation: The insulation layer, composed of aerogel blankets and polyurethane foam with a thickness of 160mm, provides excellent thermal performance and safety.

- Spray System: Employs a German-imported liquid nitrogen circulating atomization spray system.

- Air Cooling Circulation: A high-power, reinforced axial flow fan with adjustable wind speed ensures rapid and uniform freezing.

- Control System: Features a user-friendly Touchscreen + PLC automatic program control system for intuitive and reliable operation, complete with temperature monitoring and alarm functions to ensure safety.

- Maintenance: The equipment base is equipped with a drainage outlet for easy cleaning and maintenance, and is designed for long service life with low consumption of expendable materials.

Technical Parameters

| Parameter | Specification |

|---|---|

| Refrigeration Method | Direct liquid nitrogen injection refrigeration |

| Temperature Range | -196°C to -50°C (adjustable) |

| Temperature Uniformity | ±2°C |

| Control Accuracy | ±1°C |

| Capacity Options | 500L / 1000L / 1500L (customization supported) |

| Power Supply | 380V/50Hz/3PH |

| Control System | Industrial PLC + 7-inch touch screen |

| Data Recording | USB data export function |

| Material | Food-grade 304 stainless steel |

| Insulation | 120mm polyurethane high-pressure foam |

Accessories

Shelf

ShelfInter-layer spacing 100mm, 60 trays per shelf. Inter-layer spacing is adjustable.

Tray

TrayHigh-quality SUS304 stainless trays, 120 pieces of tray loaded per batch

Cart

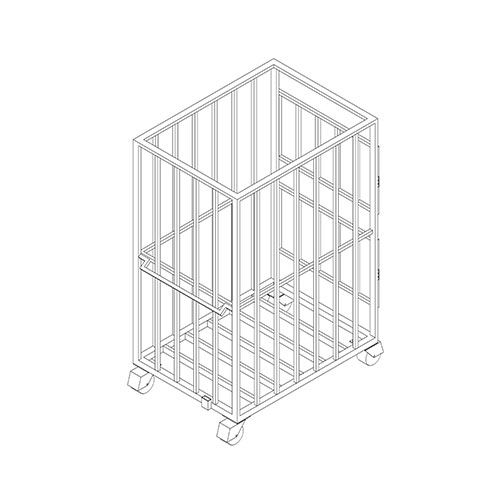

CartSUS304 cart, 700-800 kg of whole food can be loaded in each cart.

Trolley

TrolleyTrolley for loading, discharging and moving the shelves.

Advantages of Liquid Nitrogen Freezer

Ultra-Fast Freezing, Exceptional Quality

AGICO liquid nitrogen freezing cabinet utilizes advanced direct-contact liquid nitrogen refrigeration technology to achieve minute-level deep freezing. With a freezing speed 5-8 times faster than traditional equipment, it instantly passes through the ice crystal formation zone, creating microfine ice crystals that perfectly protect cellular structure. This not only maximizes the retention of the product's original color, flavor, and nutritional components but also ensures extremely low juice loss after thawing, with a taste comparable to the fresh state.

Precise Control, High Efficiency and Energy Saving

Equipped with an intelligent PID temperature control system, the temperature accuracy reaches ±1°C, and the temperature uniformity within the cabinet is controlled within ±2°C. The unique three-dimensional air circulation design, combined with the intelligent liquid nitrogen injection system, reduces liquid nitrogen consumption by over 30% and increases production efficiency by 50%. The 7-inch smart touch screen supports the storage and recall of multiple process parameter sets, enabling one-touch operation.

Safe and Reliable, Intelligent Management

The entire machine is constructed using food-grade 304 stainless steel and features multiple safety protection systems, including over-temperature alarm, pressure monitoring, door safety interlock, and oxygen deficiency alarm devices. The industrial-grade PLC control system enables fully automated operation, with optional remote monitoring and data transmission functions. It supports process parameter storage, data recording, and quality traceability, meeting the needs of modern intelligent production.

Application Fields

Food Processing Industry

- Premium seafood: Lobster, tuna, shellfish, etc.

- High-quality meats: Wagyu beef, lamb, and other premium meats

- Prepared dishes: Quick freezing of ready-to-eat products and meal kits

- Fruits and vegetables: IQF freezing of berries, edible mushrooms, and other agricultural products

Biomedical Field

- Cell preservation: Stem cells, immune cells viability preservation

- Biological samples: Tissue samples, plasma, vaccine storage

- Research applications: Enzyme preparations, protein formulation freezing

Industrial Applications

- Material processing: Deep cryogenic treatment of tools and molds

- Quality testing: Low-temperature testing of electronic components

Send Enquire Now

Send Enquire Now

-lp.jpg)