AGICO designs and manufactures mango juice processing machinery for the production of high-quality mango juice and puree, either single strength or concentrated. Mango juice processing line is mainly used to extract juice from Mango, and the production capacity ranges from 5t to 20t which can meet different requirements of the customers.

Get Price Now!

Get Price Now!

Advantages of Mango Juice Processing Line

- Mango is not selected by classification.

- Large production capacity, ranging from 5t to 20t, suitable for large and medium-sized factories.

- Adjusting certain parts of the machine can deal with different varieties of mango.

Washing and sorting

Our fruit washing machine is suitable for cleaning any fruit destined for industrial transformation. After being washed, mangos are fed to our fruit sorting machine, where they can be efficiently inspected by the personnel.

At the same time, we advise completing the cleaning with a brushing machine: the rotating brushes allow for the removal of any extraneous matter that has adhered to the fruits.

Stoning and pulp refining

Our mango destoners have been especially designed to automatically destone and peel fresh mangos: by precisely separating stones and peels from pulp, they allow for maximizing both the yield and the quality of the final product.

End products:

|

.jpg) |

.jpg) |

.jpg) |

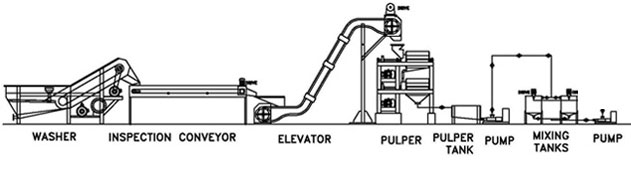

Main equipments of mango juice production line

Contact us for product catalog

Contact us for product catalog

1. Elevator

Be used to lift the fruit and vegetables into the next procedure.

Be used to lift the fruit and vegetables into the next procedure.

The elevator is suitable for lifting or transporting various materials in the food industry. The machine uses a transmission motor to drive the grid chain to rotate, so that the material can be conveyed or lifted. It can carry out horizontal conveying and inclined lifting conveying at the same time. The lifting angle during inclined conveying is usually no more than 45°.

2. Fruit sorting machine

Fruit sorting machines are widely used in fruit inspection. The frame of the fruit sorting machine is welded by stainless steel, which has the characteristics of reasonable structure, high fruit sorting efficiency and convenient use.

3. Brush and spray cleaning machine

Removing of extraneous matters and eliminating the stickiness contained on most of the mangos' peels. It performs two operations at the same time, brushing and fruit cleaning. The fruit brush and spray cleaner have a good cleaning effect and can thoroughly clean the stains on the surface of the fruit. Fruit brush and spray cleaning machine can be applied to the cleaning of various fruits, such as apples, oranges, mangoes, pineapples, lychees, kiwi, etc.

Removing of extraneous matters and eliminating the stickiness contained on most of the mangos' peels. It performs two operations at the same time, brushing and fruit cleaning. The fruit brush and spray cleaner have a good cleaning effect and can thoroughly clean the stains on the surface of the fruit. Fruit brush and spray cleaning machine can be applied to the cleaning of various fruits, such as apples, oranges, mangoes, pineapples, lychees, kiwi, etc.

4. Fruit bubble washing machine

Washing fresh vegetable and fruits and mango.

Washing fresh vegetable and fruits and mango.

Bubble washing machine are widely used in fruit and vegetable cleaning processes. The equipment replaces manual operation, saves costs and solves the problem of labor shortage. The plate part of the equipment is made of sus304 stainless steel, which is durable without rust and deformation.

5. Mango pulping machine

Separate juice and fruit slag quickly, and remove the kernel effectively. This mango pulp machine is designed to extract the pulp of most fruits and vegetables, such as mango, apple, kiwi, lychee, peach, pineapple, strawberry, tomato, etc. The central pulping unit is mounted on a heavy-duty mild steel bracket and consists of a pair of brushes that are fixed on a stainless steel shaft and finished with a stainless steel sieve. The gap between the sieve and the brush can be adjusted in the pulping machine to suit the different types, sizes and qualities to be pulped.

Separate juice and fruit slag quickly, and remove the kernel effectively. This mango pulp machine is designed to extract the pulp of most fruits and vegetables, such as mango, apple, kiwi, lychee, peach, pineapple, strawberry, tomato, etc. The central pulping unit is mounted on a heavy-duty mild steel bracket and consists of a pair of brushes that are fixed on a stainless steel shaft and finished with a stainless steel sieve. The gap between the sieve and the brush can be adjusted in the pulping machine to suit the different types, sizes and qualities to be pulped.

|

No.

|

Equipment name

|

Picture

|

|---|---|---|

|

1

|

||

|

2

|

||

|

3

|

Brush and spray cleaning machine

|

|

|

4

|

||

|

5

|

Features of mango juice processing plant:

- All mango contact parts are made of 304 stainless steel, which fully meets the food hygiene and safety requirements.

- The mango juice rate of the machine is high.

- Strong processing capacity.

- Easy to operate.

- Maximum preservation of mango's flavor and nutrients.

- The mango processing plant can produce concentrated juice/pure, NFC mango juice, diluted mango juice, dried mango slices and other configurations according to different machines.

- The production line has a high degree of automation, efficient and safe operation.