What affects the quality of fruit juice?

From raw materials to end products, in storage and transportation, all physical, chemical and microbial effects jointly and continuously act on the fruit juice. They cause the browning, souring, turbidity and precipitation of the fruit juice.

Fruit quality

The dirt, foreign matters, microbes, and decays in fruits will greatly affect the fruit juice quality. So in fruit sorting and cleaning process, we should reduce the impurities as much as possible.

People usually adopt mechanical crushing, pressing, extraction, pulping and other physical technology to produce raw fruit juice and fruit pulps. Before crushing, the fruits need precook or preheat.

To preserve the fruits according to their physical characteristics can prevent them from microbiological spoilage.

Chemical and Enzyme effects

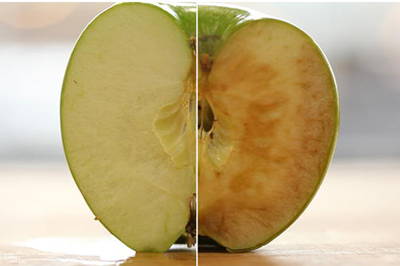

enzymatic browning

In fruit juice production process, the most important oxidordeuctases are 3 kinds:

- Phenol oxidase for catalyzing the oxidation of Poly phenolic substances,

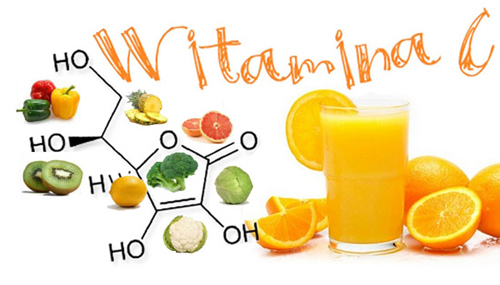

- Ascorbic acid oxidase for catalyzing the decomposition of vitamin C,

- Peroxidase for destroying hydrogen peroxide catalyzed by Aerobic dehydrogenase.

When the fruit tissues are destroyed, these oxidases can catalyze a series of reactions and turn the phenols into brown compounds.

Non-Enzymatic browning

It is also called Maillard reaction. It is paricipated by amino acid, amino compound, reducing sugar, uronic acid, vitamin C and other contents. The first reaction of non-enzymatic browning is the combination of amidogen and the hydroxyl of sugar. After a series of pinch off reaction, it becomes high molecular melanoid.

Currently, there are 3 ways to prevent Non-Enzymatic browning:

- Control the temperature and time of all production processes.

- Sulfur dioxide treatment.

- Isolate oxygen.

Aroma substance variation

Catalyzed by enzymes, the primary aroma substance in fruits will turn into aroma substance. In the same way, enzymes can turn aroma substance into other substances in fruit juice production.

Microbial effects

Microbial infection and reproduction will cause the fruit juice decay and sour, grows mildew, and muddle it up. You can take the following measures to prevent microbial effects:

- Use fresh fruits without musty, pest and disease as raw materials.

- Rinse and sterilize the fruits thoroughly.

- Strictly sterilize the workshop, equipment, pipes, and utensils. Shorten the process flow period.

- Seal the fruit juice bottle tightly after pasteurization and filling.

Sugar products use high-density sugar to prolong the preservation time of food. High-density sugar liquid generates high osmotic pressure, where the microbes are dried to plasmolysis, so their activities are inhibited. Besides, the solubility of oxygen in sugar liquid is low, which restrain the activity of microbes.

Turbidity and precipitation

Clear juice is transparent, cloudy juice should have uniform turbidity. But clear juice often have turbidity and precipitation in storage and transportation, and cloudy juice often has separated layers and precipitation.

For clear juice, this is usually cause by inadequate clarifying agent or processing time, excess proteins, oxidation of anthocyanidin, microbial pollution, or the pectin and starch are not totally resolved.

For cloudy juice, as it is a complex colloid composed of pectin, protein, and other hydrophilic colloid. The PH, ionic strength, and the content of stabilizer will have great effect on the stability of cloudy juice.

To keep the cloudy juice stable, you should lower the settling velocity to zero. According to the Stokes formula, you should make the density of particle and liquid similar, reduce the size of particles, and increase the viscosity of liquid.

How to prevent quality loss in fruit juice production?

Heat up the crushed fruit pulp and raw fruit juice properly to passivate various enzymes.

In the whole process from crushing to filling and sealing, prevent fruit pulp and fruit juice from contacting with oxygen.

- Carry out the whole process in enclosed anaerobic or anoxic environment.

- Shorten the production time so as to shorten fruit juice and fruit pulp’s contact with air.

- Add reducing substance.

- Reduce the oxygen dissolved in fruit juice by air treatment, inert gas packing, and adopting special filling system.

For kernel fruits like apple, to have cetain degree of enzyme oxydation before and during juice extraction can generate aroma substance and improve juice quality. But oxidations after extraction does no good to kernel fruit juice.

Preventing metal contamination is also important to protecting fruit juice quality. Heavy-metal salt, especially copper salt will catalyze the decompostion of Vitamin C.